Biokustik - Acoustic panels in circular fibre casting with wood fibres

Short Description

Starting point / motivation

The raw material wood has excellent and versatile properties that are used in numerous applications but have technological limits in terms of design. To increase the variety of design possibilities, wood is broken down into individual fibres by mechanical digestion and joined together to form new parts in different shapes. While the technologies used industrially for this purpose add synthetic binders and additives to the wood fibres, one of the project partners uses the so-called wet process, in which the naturally occurring biopolymers in the wood are activated by varying the process parameters pressure, temperature and time and can be pressed into hardboards in a hot press without the addition of binders. The wet process works for panels, but only to a limited extent for shaping into 3D geometries. Another project partner has expertise in the recyclable fibre casting process and can thus process cellulose pulp (also from secondary raw material sources) into plastic-free packaging with complex 3D geometry.

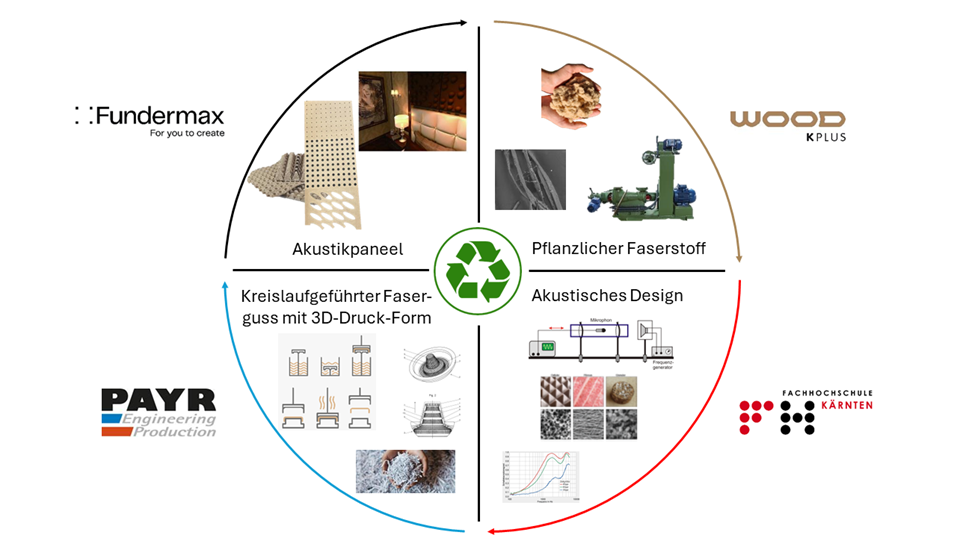

Contents and goals: In Biokustik, the consortium is pursuing the innovative project idea of making the pure wood fibre material from the wet process suitable for processing in the recyclable fibre casting technology and of acoustically designing the 3D moulded wood fibre parts (porous sound absorber) so that they can be considered for sound insulation applications. The wooden panels from the wet process are also designed to absorb sound (by means of perforations) and are connected to the porous cast fibre part to form an acoustic panel that ensures improved room acoustics. The acoustic panel consists of a single environmentally friendly material that can be reused for new 3D moulded parts after recycling (Figure 1 shows the overall concept of the project).

Methodological approach and expected results

- Development of a plant-based raw material for circular fibre casting: Methods for fibre modification will be investigated using wood fibre, which is used to produce hardboards on an industrial scale in the wet process. Recycling methods for end-of-life moulded parts and for waste from panel production will be investigated with the aim of developing secondary raw materials that can be reprocessed proportionately to the primary raw material (=closed loop) without compromising the quality of the moulded parts. Expected result: Secondary raw material share >= 20% by weight.

- Acoustic design of moulded fibre parts: The sound-absorbing property of porous natural fibres made of wood or cellulose will be used to (i) adjust the sound absorption on the material side in tests with the fibre material modifications and mixtures thereof, and (ii) to investigate the sound absorption of certain frequencies in a targeted manner with the help of consolidation (for compaction) in fibre moulding. Expected result: 1 mathematical model (finite element method) with the relevant influencing factors for the respective sound absorption class.

- Development of the cycle-guided fibre casting process with 3D printed moulds: The results on a small scale will be transferred step by step to application-oriented processing and larger moulded parts. The goals are to (i) work out optimal processing parameters with (ii) acoustically optimized fibre moulds in 3d printed A4 size and (iii) the number of material cycles without loss of quality of the moulded parts. Expected result: At least 3 material cycles; 1 optimized 3d printed A4 mould tool.

- Proof of function using the example of acoustic panel application: The development results taken together will be checked for the acoustic panel application. Expected result: 1 acoustic panel for sound absorption class in range A (highest possible rating) and D (still insulating) out of a total of 6 possible classes (A, B, C, D, E, F).

- Proof of sustainability: The results of fibre development and circular fibre casting processing will be examined and evaluated using life cycle analysis (LCA) methods. Expected result: GHG reduction >= 60% compared to a reference acoustic panel made of plastic.

Project Partners

Project leader

DI Dr. Günter Wuzella

Kompetenzzentrum Holz GmbH

Project partners

- FH Kärnten - gemeinnützige Gesellschaft mbH

- FunderMax GmbH

- Payr Engineering GmbH

Contact Address

DI Dr. Günter Wuzella

Kompetenzzentrum Holz GmbH

Altenberger Straße 69, 4040 Linz

Tel.: +43 4212 494-8012

E-Mail: g.wuzella@wood-kplus.at

Web: www.wood-kplus.at