PolyBacTex - Converting mixed textile waste into recycled fibres and cellulose for sustainable production

Short Description

Starting point / motivation

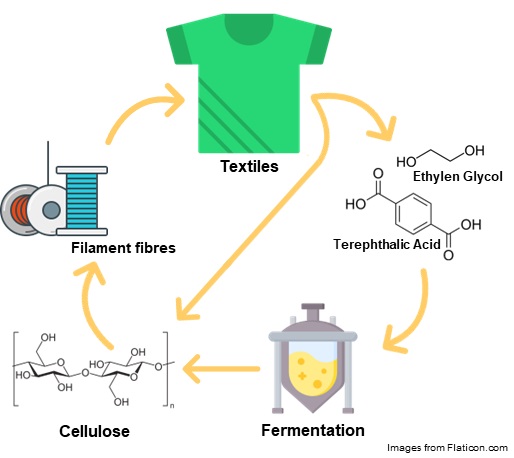

In accordance with the EU Circular Economy Package, the recycling of used textiles must be substantially reformed to enable circular economy and product life cycle extension. Currently, only 17% of textile waste is reused or recycled in Austria. A particular challenge is the recycling of mixed textiles, which requires multidisciplinary innovations along a new process chain to be generated. The successful separation of the interwoven polymers is an essential process step and part of the PolyBacTex project.

Contents and goals

In this project, HeiQ AeoniQ, together with the Competence Center Wood K plus and the University of Natural Resources and Life Sciences, is exploring alkaline hydrolysis of various textile wastes to obtain recycled fibres and store the fossil carbon from the hydrolysate in the form of high-quality biopolymers. The aim is not only to provide a proof of concept, but also to take important steps towards the economic viability of the process.

Methodological approach

The project focuses on the identification of relevant metabolic pathways and key enzymes. This is done through a combination of literature research and the use of gene databases as well as gene expression analyses. By combining adaptive laboratory evolution and synthetic biology, the project will provide a biotech platform that can produce cellulose fibres and biopolymers with high quality from polyester hydrolysate at an increased production rates.

Expected results

- Generation of processable PET hydrolysates for microorganisms and recyclable cellulose fibres.

- Microbial strain and process development to enable PET recycling in an industrial setting (scalability) using combined synthetic biology and adaptive laboratory evolution.

- Cost-efficient production of filament fibres from waste streams.

Project Partners

Project management

Michael Egermeier - Kompetenzzentrum Holz GmbH (Wood K plus)

Project partners

- HeiQ AeoniQ GmbH

- University of Natural Resources and Life Sciences Vienna (BOKU)

- Institute of Microbiology and Microbial Biotechnology

Contact Address

Michael Egermeier

Altenberger Strasse 69, 4040 Linz

Phone: +43 732 2468-6781

E-Mail: m.egermeier@wood-kplus.at

www.wood-kplus.at