AI-driven decontamination technologies for repurpose/recycle to meet food-contact regulations using light (Light-AIClean)

Short Description

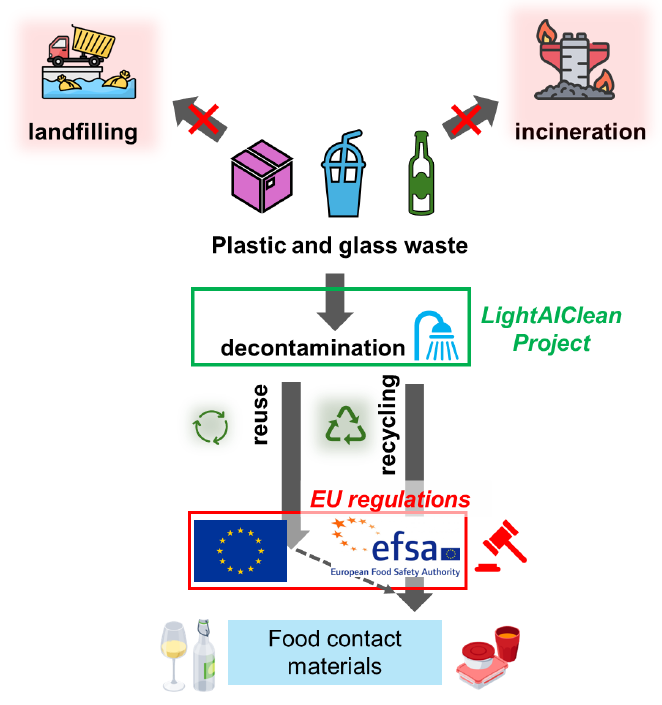

Current decontamination (DC) methods, such as hot water washing and gamma irradiation, are resource-intensive and environmentally taxing, making them unsuitable for large-scale implementation in a sustainable circular economy. To overcome these limitations, there is a pressing need for innovative, resource-efficient DC technologies that enable effective removal of contaminants while reducing energy consumption and waste production. The project addresses this need by developing an advanced DC process that integrates renewable energy sources and AI-driven optimization tools, aiming to enhance material reuse and recycling capabilities while meeting stringent EU food-contact regulations.

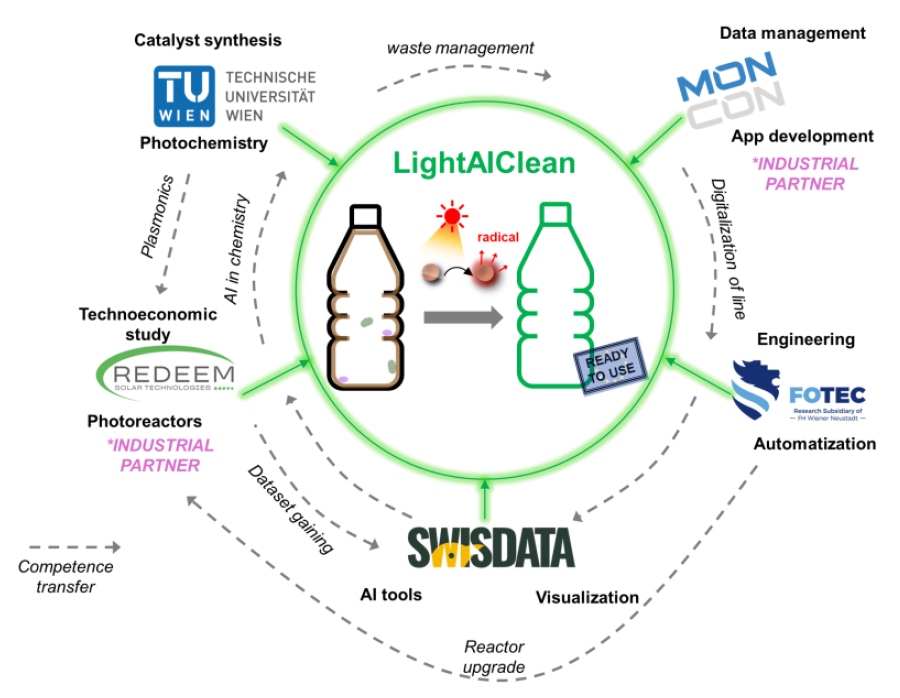

This project aims to develop: (i) a chemometrics-assisted DC process with advanced quality control powered by AI, and (ii) a novel DC technology utilizing visible light as a renewable energy source. By leveraging AI techniques, the project seeks to optimize the efficiency and sustainability of DC procedures for plastic and glass materials contaminated by plasticizers, herbicides, persistent organic pollutants, lubricant oils, and fouling agents. The final goal is to establish a scalable, industry-ready DC system that significantly enhances the circular economy by improving material longevity and reducing environmental impact. Throughout the project, potential adjustments may be made to optimize the system based on experimental findings and feedback from AI-driven analysis.

The project will develop and implement a light-driven catalytic DC system designed for multiple reuse cycles without activity loss. The consortium will use AI-driven algorithms—including neural networks, reinforcement learning, clustering, genetic algorithms, and large language/multimodal models (LLM/LMM)—to enhance process efficiency, reduce resource consumption, and optimize system performance. The methodology includes designing and testing the catalytic system in a photoreactor and integrating it into an automated decontamination setup with real-time AI feedback. If necessary, the approach may be adapted based on experimental performance and AI model refinement to ensure maximum efficacy.

The project is expected to deliver a scalable, resource-efficient DC technology that significantly reduces the environmental footprint of waste plastic and glass decontamination. Key outcomes include:

- A functional chemometric software tool for light-driven DC, with potential for broader application in standard DC procedures.

- A validated AI-driven optimization framework for efficient decontamination processes.

- A photoreactor-based system integrated with automated feedback mechanisms.

- Demonstration of sustainable, high-performance DC for critical contaminants in the recycling industry.

The project outcomes will benefit the reusable packaging industry, recycling companies, AI developers, and photoreactor manufacturers, enhancing Austria's leadership in circular economy innovations. Additionally, the integration of AI-driven chemometric techniques will set new benchmarks for efficiency and sustainability in waste recycling, contributing to greenhouse gas emission reductions, increased use of renewable energy sources, and the development of resilient, resource-efficient production systems.

Project Partners

Projektleitung

Dr. Olga Guselnikova

Technische Universität Wien

Projektpartner

- FOTEC GmbH

- SWISDATA GmbH

- Moncon GmbH

- Redeem Solar Technologies GmbH

Contact Address

Dr. Olga Guselnikova

Technische Universität Wien

Wiedner Hauptstraße 8-10, 1040 Wien

Tel: +43 588 01134 01

E-Mail: olga.guselnikova@tuwien.ac.at

Website: www.tuwien.at/phy/iap