KI4COMP - AI-based prediction of moisture distribution in composites

Short Description

Starting point / motivation

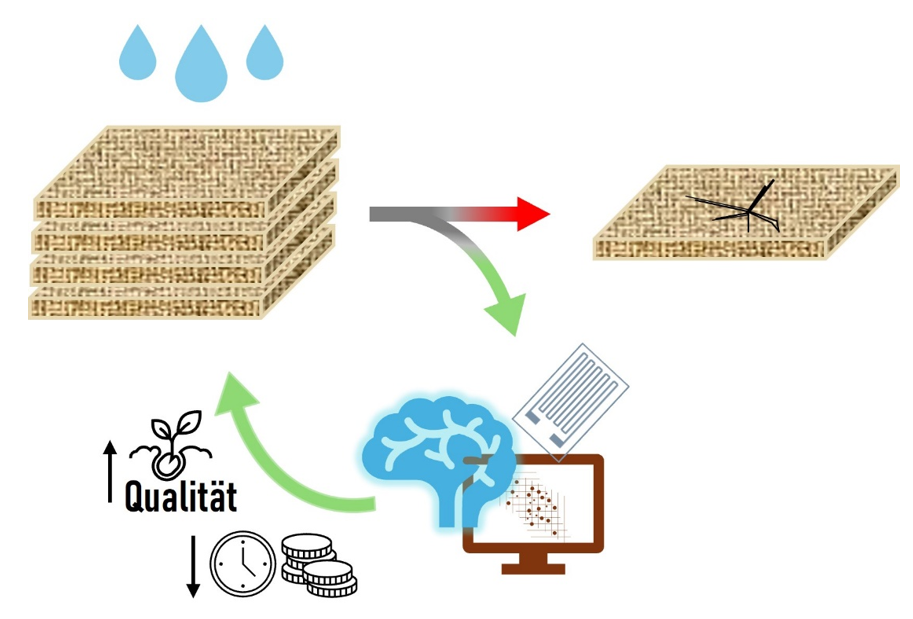

The precise prediction of moisture distribution and mechanical properties of composite materials is essential for developing resource-efficient and high-performance materials. By utilizing AI and integrated sensor technology, this project aims to simplify traditional simulation methods, shorten development times, and promote sustainable material innovations.

Contents and goals

The goal of this project is to develop an AI model capable of predicting the moisture distribution and mechanical properties of various composite materials under different environmental conditions. Compared to conventional simulations, this approach will significantly improve accessibility to such predictions. The resulting time and resource savings can then be redirected toward enhancing innovation and efficiency.

Methodological approach

To develop the model, various composite material samples will be equipped with integrated moisture sensors and tested under defined conditions. By considering parameters such as fiber material and resin matrix, the model will enable immediate and accurate predictions. Another key focus is the increased use of natural fibers in composite material production to expand their market share and support sustainable product development. The implementation of novel paper-based sensors will enhance the understanding of natural fiber composites, which are particularly sensitive to environmental moisture. A significant aspect of this project is the application of AI technologies for model development, which is expected to reduce the need for extensive laboratory testing and resource-intensive prototype manufacturing in the future.

Expected results

Overall, the project aims to facilitate the development of new material combinations, improve product design, extend product lifespan, and reduce resource consumption during development and production. The project follows the CRISP-DM methodology for creating high-quality datasets and predictive models. Additionally, a life cycle assessment (LCA) will be conducted to evaluate the environmental impact of the AI model compared to conventional methods and to analyze the longevity of the optimized material compositions.

Project Partners

Project leader

PD DI Dr. Arunjunai Raj Mahendran

Kompetenzzentrum Holz GmbH – WOOD KPLUS

Projectpartners

- Fraunhofer Austria Research Gesellschaft mit beschränkter Haftung

- KÄSTLE GmbH

- R&D Consulting GmbH & Co. KG

Contact Address

PD DI Dr. Arunjunai Raj Mahendran

Kompetenzzentrum Holz GmbH

Altenberger Straße 69, A-4040 Linz

Tel: +43 4212 494-8016

E-Mail: a.mahendran@wood-kplus.at

www.wood-kplus.at